If you look on the Ford truck enthusiast forums, there’s a great deal of discussion regarding the cooler bypass tube and the integral pressure relief valve. A common misconception is that this tube is used to control transmission fluid temperature, i.e. when the fluid is cold, the tube bypasses the cooler. Nope; Its a pressure relief valve.

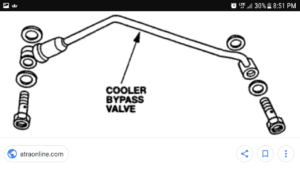

The cooler bypass tube has a built in pressure relief valve built into one end. The tube is attached to the side of the transmission with the same flow-through banjo bolts that are used to attach the transmission cooling lines.. Fluid comes out of the front fitting and goes to the transmission cooler(s). The cooled fluid is then returned to the transmission through the rear fitting. If for some reason the transmission cooler circuit becomes plugged or restricted, the tubes pressure relief valve opens and allows transmission fluid to flow through the tube instead of through the cooling circuit. The downside is, if this valve becomes weak or jams open, the tube will bypass all the time and reduce flow through the cooler, possibly causing the transmission to overheat.

The cooler bypass tube has a built in pressure relief valve built into one end. The tube is attached to the side of the transmission with the same flow-through banjo bolts that are used to attach the transmission cooling lines.. Fluid comes out of the front fitting and goes to the transmission cooler(s). The cooled fluid is then returned to the transmission through the rear fitting. If for some reason the transmission cooler circuit becomes plugged or restricted, the tubes pressure relief valve opens and allows transmission fluid to flow through the tube instead of through the cooling circuit. The downside is, if this valve becomes weak or jams open, the tube will bypass all the time and reduce flow through the cooler, possibly causing the transmission to overheat.

With this in mind, there are two trains of thought regarding the cooler bypass tube;

1) ELIMINATE TUBE

Eliminate the tube entirely and force all fluid to flow through the cooler. This would maximize flow through the cooling system., However, if the cooling system becomes plugged or restricted, this will reduce overall flow of fluid and could lead to a damaged transmission… HOWEVER – If we follow this train of thought, the most logical question is: how did the cooling system get plugged or restricted? If the transmission is self destructing, then it could be shedding material and may be causing the cooling system to get plugged? Unless you can come up with a way to plug/restrict cooler flow, then deleting the tube entirely makes sense..

The easiest way to eliminate the tube is to replace the tube with special spacer bushings and re-use the original banjo bolts.

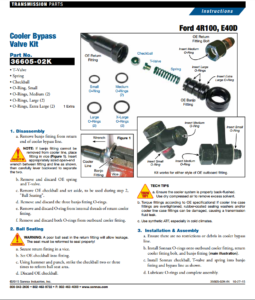

Rebuild the tubes pressure relief valve to restore the tubes full functionality. If the pressure relief valve is operating normally, and the cooling system isn’t restricted, then there will always be full flow through the cooling system. If the cooling system does become restrictive, then the relief valve will bypass and allow flow to the rear of the transmission. Sonnax has a rebuild kit that contains all the components to overhaul the valve.

CONCLUSION

After considerable time researching the two options, I decided that both options were valid. However, having a functional relief valve would offer the additional protection in the extreme and unlikely event that the cooling system became plugged.

After considerable time researching the two options, I decided that both options were valid. However, having a functional relief valve would offer the additional protection in the extreme and unlikely event that the cooling system became plugged.

Overhauling the tube – Remove the cooling lines from the tube, then remove the banjo bolts that hold the tube to the transmission. There should be two aluminum crush washers on each banjo fitting. A little bit of fluid will drain out from each end when the cooler lines and banjo fitting are removed, I’d say no more than a 1/2 cup. The tube will also have fluid in it so have some paper towels ready.

The Sonnax instructions are simple. Before starting, I open the package and inventoried all the parts. Watch the ball as it will roll away. I laid all the parts out, specifically the different size o-rings so I could identify the different sizes when they are called out in the instructions.

The valve assembly simply pulls out of the tube. I needed to place the end in a vice and pry a little. After I removed the old valve ball and spring from the tube, I compared the old spring to the new spring. The old spring wasn’t what I would consider worn. It took a lot of force to compress it. HOWEVER, the new spring was a lot stiffer, and took a lot more force to compress it.

I looked down inside the tube to inspect the ball seat. It looked OK, but I followed the instructions on resurfacing the seat. I placed the valve body in a vice, dropped the old ball into the seat, then using a flat punch, struck the ball a few times to re-surface the seat.

I cleaned all the parts, then used a thin film of silicon paste on the new ball, spring and o-rings when I re-assembled.

I cleaned all the parts, then used a thin film of silicon paste on the new ball, spring and o-rings when I re-assembled.

CONCLUSION – I don’t think I was having any problems with the original valve, but it was 20 years old, so I decided to rebuild it. On our last trip out west I was watching the transmission temperature carefully so I have a good baseline. I’ll watch it again this fall and I see if there is any difference.

My granny is brand new and new cooler if it’s overheating could it be caused by pulling a trailer with a vehicle on it. We are super close to the max weight of the pull on hotorhome. Should take off back trailer and see if it helps? Broke down in Georgia, TRYING TO GET HOME,TEXAS!!!!!!

Pingback: Upgrade report - A little more power and better fuel economy - 1999 Southwind 35S

Biggest flaw in the design of the transmission and cooler system from factory is the cooler it self. I have the 4r100 behind my 7.3 powerstroke and and highly recommend getting a 33 or 37 row cooler that came out with the 6.0 powerstrokes. Unless pulling a heavy load or in the mountains you shouldn’t see much more the 70° above outside temp on your transmission